| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | Fine-Tech |

| Model Number : | B40 |

| Price : | Negotiation |

| Delivery Time : | 5-15 work days |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 2000t per year |

| Certification : | ISO9001 |

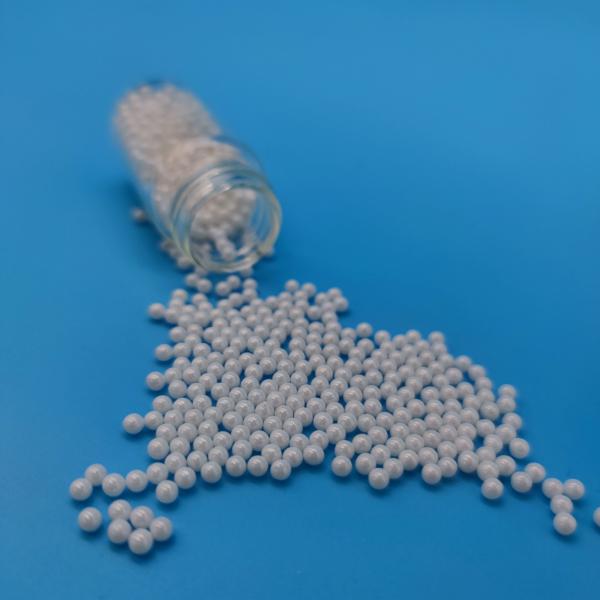

Z series Ceramic beads shot peening media and B series Ceramic beads blasting media have proved to be the ideal solutions. Made up mainly of zirconia,

these ceramics are produced by melting high-quality imported zircon

sand into liquid at a high temperature and then spraying it into

balls before being sieved and magnetically separated. As a result,

particles with a high roundness, strength and uniform particle size

are obtained. The high hardness, strength and smoothness of the

zirconia Ceramic Beads allow them to create a gentle grinding

effect, which results in a uniform surface profile and matte finish

without introducing any contamination to the metal body. They are

widely used for sandblasting and surface treatment in industries

such as aviation parts, stainless steel plates, medical devices and

automotive components. Furthermore, the low dust content, high

degree of sphericity and high toughness ensure their excellent

performance and are perfect for providing high quality components

with an aesthetically pleasing appearance.

White color, high sphericity and smooth surface beads.

Utilization rate(20 – 30 times) higher than glass blasting media.

High hardness, unbreakable, can be recycled and used repeatedly,

long service life, reduce energy consumption and reduce costs.

Lower metal surface roughness.

Less operation pressure and reduced abrasive velocity needed than

glass blasting media, thus have far less abrasive breakdown and

dust generation, results in cleaner working environment and better

operator visibility.

Strong mechanical resistance and high toughness, but gentle with

equipment and tools preserving work parts, and no metallic

contamination for treated parts.

Lower wear rate

Ceramic beads has smooth surface and round solid shape,it can be

rebunded in multi-angles,so it has lower wear rate in blasting

process

High hardness and toughness

Ceramic beads contains 62-66% ZrO2,it has higher hardness over

700HV and fracture toughness, which will play an important role in

blasting process.

|

|---|

Sandblasting with ceramic beads can produce a uniform and uneven

rough surface on the cleaned surface to facilitate mechanical

bonding of the coating. Using clean compressed air to drive clean

ceramic sand to spray on the surface of the workpiece can generate

compressive stress on the surface of the substrate, remove the

surface oxide film, and cause lattice distortion of part of the

surface metal, which is conducive to the physical bonding of the

coating. The substrate metal can be sandblasted to obtain a clean,

rough and highly reactive surface. This is an important

preprocessing method.

The quality of the pre-treatment of the sandblasting process

affects the adhesion, appearance, moisture resistance and corrosion

resistance of the coating. If the pretreatment work is not done

well, the rust will continue to spread under the coating, causing

the coating to fall off in pieces.

New application areas include medical treatment, the high iron

industry, automotive, mold and machining and electronic equipment.

For example, ceramic beads can be used for deburring of stainless

steel surgical instruments and titanium alloy human implanted

devices, to improve the metal texture and form a smooth satin

effect for grinding and finishing of high-speed rails, to clean the

welds and welding spots on the car floor, and to prepare for

subsequent spraying, to improve fatigue life of automobile springs,

to eliminate stress and improve impact resistance for aluminum

alloy car wheels, to improve surface finish of stainless steel

molds, copper moulds and aluminum alloy moulds, to clean the flash

and burr of machined parts, as well as to sandblast the shells of

mobile phones, tablet computers and watches made of aluminum alloy

or stainless steel, so as to adjust the roughness and gloss of the

surface as required.

Brand Name: Fine-Tech

Model Number: B40

Place of Origin: Changsha, China

Minimum Order Quantity: 500kg

Price: Negotiation

Packaging Details: 25kg/barral, 25kg/bag, 1t/pallet

Delivery Time: 5-15 work days

Payment Terms: L/C, T/T

Supply Ability: 2000t per year

Cost: Moderate

Material: Ceramic

shape: Particle

usage: Deburring

Zro2: 65%

Ceramic Bead Abrasive, Ceramic Beads Blasting Media, Ceramic Beads Blasting Media for Sale

we provide technical support and service for our ceramic bead

blasting products. Our technical support team is available to

answer any questions you may have about our products and services.

We offer a comprehensive range of services including installation,

troubleshooting, repair, and maintenance. We also offer training

programs to help you become familiar with our products and

services.

Our technical support team is available 24/7 to answer any

questions you may have. You can contact us via phone, email, or

live chat. We are committed to providing the highest level of

customer service and support.

Ceramic Bead Blasting Packaging and Shipping:

The ceramic bead blasting product must be packaged and shipped in

accordance with the following requirements:

|